If not detected early, arcing causes erosion of anaodization at the chamber and generates particle.

Arcing is basically a breakthrough in an insulating layer at the chamber wall, where ever potential grown-up.

Reasons for arcing are:

- Inhomogeneous polymer build-up at chamber wall.

- Incorrect grounding of parts of chamber.

- Leakage currents (ESC).

Effect on wafer / process:

Particles generation reduce the yield.

Hardware related effect:

Arcing heavily destroys chamber parts.

Effect on plasma parameters:

The plasma density is sharply decreased for short times.

Collision rate:

- increase: large polymer molecules,

- decrease: relative small metal ions.

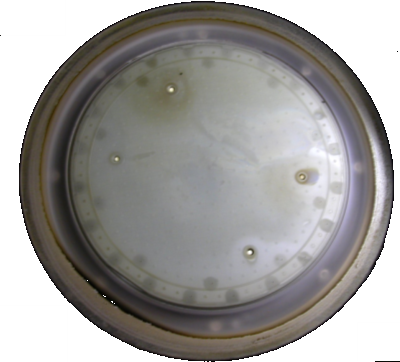

The plasma instabilities in the diagram above (red) indicate arcing at the e-chuck. Erosion of the anaodization near the lift pin holes are shown in the picture below.

|